Servo tank gauging instruments offer high precision measurement for liquid level, interface and density applications. The devices fulfill the exact demands of tank inventory management and loss control and are optimized in regards of total cost saving and safe operation. Check out the broad range of Proservo devices for servo level applications and click on the button below.

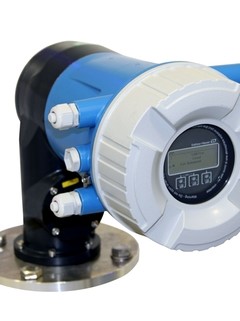

Servo instrument with high precision measurement of level, interface and density for liquid.

Predecessor model: Proservo NMS5

Servo instrument with high precision measurement of level, interface and density for liquid.

A small displacer is accurately positioned in a liquid medium using a servo motor. The displacer is then suspended on a measuring wire which is wound onto a finely grooved drum housing. When the displacer is lowered and touches a liquid, the weight of the displacer is reduced by liquid buoyancy force. As a result, torque in the magnetic coupling changes, which is measured by 5 sets of Hall sensors.