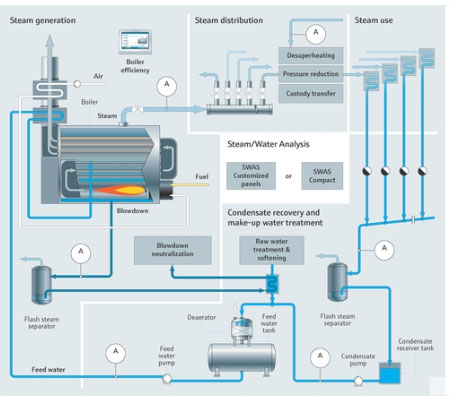

With our sophisticated SWAS solutions, you have the quality of your feed water completely under control. Take advantage of highly efficient monitoring of multiple, even complex parameters at a central location. Consistently pure water helps to minimize process downtime and prolong the life of your power plant. You reliably comply with limit values; traceability and secure data management provides proof of water quality at any time. The turnkey systems are easy to commission and operate.